A History Lesson – The Need for Power in Northern Arizona

No history of the BM&LP would make much sense without first understanding the plant it was built to service – the huge Navajo Generating Station, located just southeast of Page, AZ, on the northern end of the Navajo Nation.

In the early 1960s, the US Bureau of Reclamation (USBR) started working on an ambitious project to alleviate the chronic water shortages of the lower Colorado River basin area – particularly Arizona, California, and to some extent, Mexico (in that they are guaranteed 1.5M acre-feet of water in the Colorado annually). The area had grown by 7.5 million residents in the thirty years between 1930-1960, and both power and water were needed to sustain the explosive growth.

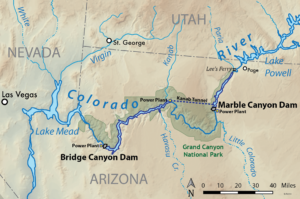

The USBR’s initial “Pacific Southwest Water Plan” of January 1964 proposed building two additional dams on the Colorado River – Bridge Canyon Dam and Marble Canyon Dam. Marble Canyon Dam would be located about 30 miles below Page, near the east end of Grand Canyon National Park. Bridge Canyon would be at the other end of the park, with its pool backing up about 14 miles adjacent to and then into the Grand Canyon National Park itself. The PSWP notes that while this would not necessarily be a popular move, but it was foreseen when the park was created, and a narrow reservation for such infringement was written into the 1919 act creating the park.

The problem was that there was too little drop between Glen Canyon Dam in Page and Marble Canyon. Marble Canyon Dam itself would only be ~310 feet high (as opposed to Glen Canyon which is 710’, Hoover at 726’) and impound a rather small reservoir. So, a ~40 mile tunnel (some sources say 38, some say 44) known as the Kanab Tunnel was proposed from Marble Canyon Dam to a main power station located deep in the Grand Canyon National Park itself. This tunnel would provide the turbines with ~1300ft. of hydraulic head, enabling efficient and large scan power generation in the neighborhood of 750 megawatts, but would reduce the flow of the Colorado through the park to a trickle (~1000 cubic feet/second).

These two dams combined were intended to provide 2-3 gigawatts of electrical power, much of which was needed by the Bureau itself to operate the pumps needed to make the Pacific Southwest Water Plan work. The PSWR would pump Colorado River water 336 miles through the desert to the growing cities of Phoenix and Tucson. The excess power would also be sold to a variety of regional utility companies, feeding into the grids of Arizona, Nevada, and California and helping to offset the cost of dam construction to the taxpayers.

Needless to say, the idea of submerging and industrializing the Grand Canyon created a significant amount of resistance from both the National Park Service, environmentalists, and the public in general. While apparently government bureaucrat thinking in the 1960s had not yet come around, the public was adamantly against it.

The compromise was a large coal-fired generating station instead of the two dams. Signed into law on Sep 30, 1968 as public law 90-537, the Central Arizona Project was created. The Central Arizona Project was the Pacific Southwest Water Plan made manifest – an authorization to turn years of planning into a working system of public infrastructure needed to deliver 1.5 million acre-feet (489 trillion gallons) some 336 miles south through the arid Arizona desert. The act (in section 303a) prohibited the US BoR from constructing any dams between Hoover and Glen Canyon, effectively ending any discussion of the Marble Canyon or Bridge Dams. Further, 303b authorized them to partner with private utilities to construct thermal (coal) power plants and transmission infrastructure as needed to power the Central Arizona Project.

Thus, the Navajo Generating Station (NGS) in Page, AZ, was born. The Bureau (owning 24.3%) and the partner utilities (Salt River Project, Arizona Public Service, Tucson Gas & Electric, Nevada Power, Los Angeles Department of Water & Power) would get their thousands of megawatts of generating capacity, and the last free waters of the Colorado River would be left alone.

Constructing the Navajo Generating Station

The problem with building a large coal-fired plant – and by all accounts, a 2250 megawatt plant is a large plant – in the middle of the desert, far away from transportation, is that you need to find a way to get it a reliable source of fuel. Normally that’s not an issue – you locate the plant near a rail line, and haul coal in from mines far away. In this case, however, Page was 130 miles from the nearest rail line – the Santa Fe in Flagstaff. Other options would have included the D&RGW at Moab or the UP in southwest Utah, but both of those options would have involved building through incredibly difficult terrain.

Some 78 miles to the southeast of Page is a long mountain known as Black Mesa, standing about 8200 ft high against the background of high desert. Locals have mined coal here for use since prehistoric times, but the ridge had come to the attention of Peabody Coal around 1960. At the time, the Mohave Generating Station was being constructed in Laughlin, NV, and rather than move coal by rail, the proposal was to move it in a pipeline as a slurry – a mix of crushed coal and water. The project was unique for its time – the 273 mile, 18″ diameter slurry pipeline would be the furthest slurry transportation attempted to date. Initial leases were signed in 1964 with the Navajo for approximately 25000 acres, and in 1966 another 40000 acres was leased from both the Navajo and the Hopi, as the lease area overlapped the border between the two. The first mine opened on the lease was the Black Mesa, and by 1971 it was sending liquefied coal to Nevada.

The NGS would be fed coal from the same lease lands, but from a second mine further to the east – the Kayenta Mine. However, instead of a second slurry pipeline, the coal would be moved by conveyer belt to a loading silo, and then to the power plant by an electrified railway. Thus, the Black Mesa & Lake Powell Railroad was born – 78 miles of single track railway linking the loading silo at the foot of Black Mesa with the NGS plant on the banks of Lake Powell. A more apt railroad name could not have been chosen.

I can’t find any exact reasoning as to why a railway was chosen over a slurry system, but it seems a far more rational choice. The slurry pipeline moved coal effectively, but it had a downside – it needed 1.3 billion gallons (about 3000 acre-feet) of water every year to keep it operating. That may not sound like much, but in the middle of a parched desert with next to no rainfall, that’s a lot of water to pull from an aquifer. An electric railway, on the other hand, uses only power from the plant it’s feeding. The terrain between the two ends is not terribly challenging, particularly for coal loads that would primarily be going downhill from the mine to the plant.

Construction on the plant itself began in 1969. The NGS would consist of three individual boiler/generator blocks, known as Units 1-3. Unit 1 would come online in 1974, followed by #2 in 1975 and #3 in 1976. Morrison-Knudsen was contracted to construct the railway at a cost of $54M, and began the task in February 1971.

The line’s engineering was quite progressive. Track engineering allowed for a 2.5% ruling grade for empties but only a 0.4% ruling grade for loads. Mainline curvature was limited to 2.5 degrees maximum. The line was designed for electrified operation running at 50kVAC – a record in North America at the time. This high voltage allowed for the overhead to only be fed from the plant end, which negated the need for substations or additional transmission lines. The track was entirely constructed with concrete ties – a novel idea at the time in North America – and 119lb welded rail. Special 125-ton capacity slab side steel coal hoppers were ordered (providing an axle loading of ~40t), designed to be run as an 50-car set. Finally, the line was designed to be completely automated using technology pioneered on the Muskingum Electric Railroad in Ohio. Each train was intended to only have a caretaker aboard the locomotives in case something with really, really wrong.

The first three GE E60C electric locomotives (BMLP #6000-6002 – 6000 would be renumbered 6003 upon delivery) arrived in Flagstaff in May 1973, and were disassembled and trucked north to the railway. The overhead was energized for test runs in August of that year, and initial coal runs began in October. NGS Unit 1 went into production operation in January of 1974, running on Black Mesa coal hauled over 78 miles of new electrified railroad.

Sometimes Things Don’t Quite Work Out

This shining example of engineering progress didn’t exactly work out as planned. From the track structure to the automated operations, nearly all of the innovations didn’t pan out.

The fastener systems on the concrete ties were one of the first things to fail. An early study showed that the pads under the rail allowed too much movement, causing a quarter of the ties to have severe concrete spalling around the rail seat, and between 5-10% to have cracks in the center portion of the ties. In addition, the original hardware was mild steel, which failed at an alarming rate. New high strength bolts and high-density polyethylene pads were installed only two years into operations, and eventually concrete ties were replaced with wood on many of the curves. That lead to its own problems, as the ballast was mostly uncrushed round river rock, which lacked the sharp edges needed to lock the wooden ties in place. (Apparently this contributed to at least one derailment.) Curves were canted for 55mph operation, but the heavy trains couldn’t maintain that speed. When combined with the high axle loading, this caused excessive shelling of the rail head and wear on the wheelsets.

By 1976, admitting some defeat, the railroad ordered three more E60C locomotives (#6004-6006) along with 40 conventional 100-ton hoppers, and restricted loading of the original 50 hoppers to 100 tons as well. The idea was that two trainsets or longer trains running slower (40-50mph rather than the design 55mph) could deliver the same amount of coal as the initial super-heavy train could.

The automation was abandoned in 1977, as GE and the BM&LP never could get it to work reliably. The system was not dynamic, instead relying on a set of transponders mounted between the rails to tell it where it was and thus when to brake, accelerate, blow the horn, etc. In addition to being vulnerable to weather and vandalism, these static elements couldn’t compensate for elements like wet rail, heavier-than-expected loads, and missed transponder signals. There are even reports that debris between the rails, such as beer cans, could confuse the inductive receivers and trigger untimely events, such as the horn going off in the middle of nowhere. Due to the frequent problems, the BM&LP scrapped the system and reverted having a qualified crew in the cab.

Regular Operations

By the late 1970s, the railroad had settled into its routine – three trips a day (leaving NGS at 0600h, 1400h, and 2200h), six days a week (every day but Wednesday), moving some 26,000 tons of fuel every single day. Aside from the occasional derailment or maintenance emergency, that would be the pattern right up until the end some 40 years later.

The most major change in equipment came in 1999, when the line acquired eight ex-NdeM E60C-2 locomotives – EA004, EA022, EA023, EA032, EA034, EA036, EA038, and EA039 – to replace the aging, high mileage original E60Cs. These engines were built new in 1982-1983 for freight service on Ferrocarriles Nacionales de México’s (NdeM) new electrified, double track Mexico City-Queretaro mainline. That said, because the project was a bit of a government boondoggle, they were purchased at the very beginning of the project and consequently held in storage for 12 years until the line opened in 1994. Few of them ever ran revenue freight, and all were idled again when the line was privatized, sold to TFM / KCSM, and de-electrified in 1997. While these engines were built for 25kVAC service, the BMLP upgraded six to 50kV inputs and scrapped the other two for parts. Only one was ever repainted into BM&LP colors – the rest continued in NdeM paint until the end.

The Conveyor

I feel no discussion of the Navajo Generation Station and the Black Mesa & Lake Powell is really complete without at least a cursory discussion of the conveyor. It’s an impressive piece of engineering and deserves to be remembered in its own right.

The railway actually ends at the loadout silo, which is at the northern base of Black Mesa. The mines, on the other hand, lie up and over on the back side of the mesa. A conveyor system carries coal some 17 miles from the furthest part of the mine all the way to the silos, passing through a number of loading points where coal is transferred from mine trucks to conveyor as well as a number of angle stations where the belts change direction.

The Countdown Begins

In the end, it would come down to economics. The low price of natural-gas fired generation ($32/megawatt-hour in 2017, vs $38/MWh for NGS), increased environmental compliance costs on both the plant and the mine, and an aging plant caused the owners to vote to shut the plant down at the end of 2019 unless a buyer could be found. Nobody stepped up, and the countdown began. Navajo Generating Station, the Kayenta Mine, and the Black Mesa & Lake Powell would all cease operation by the end of the year.

For the environment, this was a win. For years the plant was associated with hazy skies and a yellow-brown streak that could be seen for a hundred miles in the otherwise pristine skies around the Four Corners region. That’s not to say the plant’s owners didn’t do what they could The plant itself received continuous upgrades over the years, trying to make it better. Fly ash precipitators were put on almost immediately in 1976. Wet sulfur dioxide scrubbers were added to all three units in 1997-1999, decreasing SO2 emissions by 90%. New more effective precipitators were outfitted in 2003-2005. Low nitrogen oxide (NOx) burners were installed starting in 2009. But under 2011 EPA rules on mercury and other toxic emissions, the plant would have been in for another ~$500M worth of upgrades if it hadn’t shut down in 2019.

For the locals, there seem to be a lot of complicated feelings. The plant and the mine provided a huge amount of good jobs and revenue in a part of the US where few other such opportunities exist. The plant itself employed around ~540 people and paid $52M annually in wages. Leases, taxes, and fees paid to the Navajo Nation amounted to another ~$3.5M annually. Additionally, the mine employed an additional 430 people, paid $47M annually in wages, and paid $37M to the Navajos and $13M to the Hopis in royalties and fees every year. Many of the employees were lifers, spending most of their working careers there, so there’s a huge amount of pride and loyalty in the workforce. That resonated through even in my brief conversations with the employees I encountered. But, there’s also a continued sentiment among some on the reservations that they’re getting stuck with environmental damage and not seeing a lot of the benefits. You have to remember that some 15,000 rural homes on the Navajo reservation still are not connected to the electric grid, some sitting right in the shadows of the 500kV lines that take NGS power to faraway places like Phoenix and Tucson. Like I said, it’s complicated.

The Last Days – August 24-26, 2019

Through the railfan grapevine, I learned that the final coal was delivered (by the ~13 mile conveyor) from the mine to the coal loadout somewhere around Thursday, August 22. At that point, enough trains would run to empty the silo. Given estimates garnered from Salt River Project crews at the loadout, that would probably be Sunday, August 25.

Saturday, August 24, 2019

Since I’d never actually managed to see the BM&LP out and doing anything, it was pretty much now or never. Early Saturday morning, August 24, I sent my boss a note that I wouldn’t be in on Monday and headed out for Page. While I was in a hurry, I did catch some headlights just west of Fort Garland, CO. Since the San Luis & Rio Grande’s future was only slightly brighter than the BM&LP, I decided a few minutes of detour were justified. Nothing like an E9 and a leased ex-CSXT SD70M pulling a passenger train in 2019.

Arriving at the loadout late Saturday afternoon, I was surprised to find that the afternoon train was still loading. If things were running according to schedule, it should have been back at the plant or even out on the line somewhere. But being the last weekend, nothing was quite running on time. Fortunately, I ran into some fellow fans I knew at the crossing just west of the loadout, and they got me up to speed on what was going on. Yes, indeed, at that point there were roughly ~4 train loads of coal left in the silo. One would normally run overnight, leaving the plant around 10. However, given that the train loading was already hours late, that would likely be delayed. So that left two daylight trains on Sunday, and then the final run overnight on Sunday into the early hours of Monday morning.

It took forever for the afternoon load to head out that Saturday afternoon. We all waited in the excellent golden evening light, but as time wore on, more and more fans bailed for elsewhere. Having nowhere else to really be, I stuck it out. Sure enough, just after sunset they finally got underway – about 8pm. That put them at around ~2 hours late from normal, which I figured would be important to gauge the morning train.

I picked off a few shots just west of the loadout, but it quickly got too dark to shoot at all. I chased the train over to where it starts climbing away from US 160, and then called it a night and turned in for some food and sleep in Page.

Sunday, August 25, 2019 – The Last Day

Factoring in the previous night’s delay of 2 hours to the typical 6am departure time out of the plant, I figured if I got to the overpass south of NGS by 7:45am I’d be fine. Late trains get later, right? No such luck. No railfans at the bridge when I got there, no train in the plant loop. But I could hear the EOT device blipping away on the scanner, so I figured he couldn’t be that far ahead. I headed towards the mine and caught sight of the power just coming up on Kaibeto. Without time to catch it at the Kaibeto crossing, I proceeded southward along BIA Route 21 to catch it at the overpass. From there it was a simple task of following it into the mine.

The rest of Sunday was spent chasing the loads back to Page, waiting a couple hours, and then chasing the afternoon empties back to the mine. Much like Saturday, by the time the afternoon turn was loaded and ready to go back, the sun had set and the light was gone. Locals, friends and family of the employees, and railfans from across the country were out to witness the last runs.

The final train left Page in the middle of the night on Sunday and returned to the plant just as the first rays of the sun were piercing the horizon Monday morning. There were plans to put the one original BM&LP E60Cs on the front, but those plans fell through. There were also rumors of one more train running on Monday to empty out a bit more coal left in the silo, but the decision was made to just write the coal off instead. Instead, the train arrived at the plant as had been done thousands of times before, albeit with a little fanfare for a media event that morning. Once the cars were unloaded, the pans were dropped and 45+ years of electric railroading in Page came to a rather unceremonious end. At least there was decent warning, so the passing of the BM&LP was well recorded.

When the Wires Came Down – Jan 18, 2020

The week after the final train ran, the overhead was cut at any point it crossed a road or went under a power line. While the Navajo Nation has negotiated keeping the right of way and track structure, the overhead was deemed surplus and would be dismantled and scrapped.

I had to head to St. George, UT, to pick up some things in mid-January, so I routed myself again via Kayenta and Page to see what had become of the BM&LP. Just past the loadout it was obvious that the overhead was coming down. In the week following the last train, the lines had been de-energized and cut anywhere they crossed either a road or another power line. Presumably this was to minimize any hazard, either to vehicular traffic or the risk of the line becoming accidentally energized should a power line fall on it. The cuts were made without removing the tensioning from the cables, and as a result, the wire ripped the support structures apart violently when it recoiled. Many of the arms were broken off their insulators, and sometimes entire poles were snapped off. With the line safely sectioned and moved away from energized wires, it would be easier to ensure the safety of those scrapping out the system.

Nearer the plant, crews were in the final stages of cleanup. Only a few piles of support arms and a few broken insulators still lay on the ground. Even on Saturday, a small loader was working up and down the grade, carrying the piles of debris off to their demise. In a few months, the overhead will be gone, the equipment will be scrapped, and all that will be left is two rusting strips of steel through the desert, waiting for some unknown future purpose that may never come. In a few short years, the mine and the plant it served will also vanish into memory, and a chapter of northern Arizona history will come to a close forever.

Everything in this trip report was shot with a Canon 5D III and a 28-300mm f/3.5-5.6L lens.

This work is copyright 2024 by Nathan D. Holmes, but all text and images are licensed and reusable under a Creative Commons Attribution-NonCommercial-ShareAlike license. Basically you’re welcome to use any of this as long as it’s not for commercial purposes, you credit me as the source, and you share any derivative works under the same license. I’d encourage others to consider similar licenses for their works.